For further details, please register for, and attend the ATTMA Future of Airtightness event on the 10th January 2024 at The Building Performance Hub, High Wycombe.

The revised Approved Document L of the Building Regulations in England and Wales mark a significant transformation in the construction industry, especially in achieving airtightness in buildings, more so than the industry may realise. This change signals the end of the long-standing practice where contractors predominantly used internal plasterboard as an air barrier, supplemented by sealants like mastic and foam to control air leakage. The revised regulations introduce more stringent airtightness targets by default, necessitating a comprehensive re-evaluation of these traditional methods.

Traditionally, plasterboard has been a favoured choice in construction due to its cost-effectiveness, ease of installation, and versatility. In terms of air barriers, it offered a straightforward solution to meet the previously less stringent airtightness requirements. The combination of plasterboard with sealants allowed for a relatively simple method to decrease air leakage in buildings, particularly during the finishing stages of construction, “what you see is what you deal with”. However, this method falls short under the new, more stringent airtightness targets.

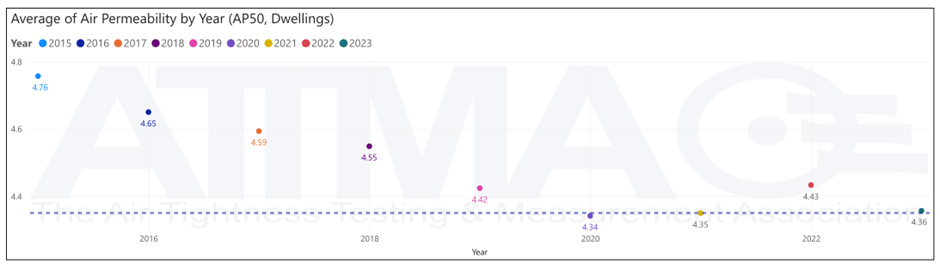

The revised Approved Document L, though the maximum benchmark of air tightness has only slightly reduced (from 10.00 m3.h-1.m-2@50Pa down to 8.00 m3.h-1.m-2@50Pa), realistically the target will now move from an average of 4.36 m3.h-1.m-2@50Pa to around 3.00 m3.h-1.m-2@50Pa depending on the building construction and varying factors. This change is aligned with global efforts to enhance energy efficiency and environmental sustainability in the construction sector. Lowering air leakage is a critical step in reducing buildings’ energy consumption and carbon footprint, emphasising the need for more effective air sealing methods from the initial stages of construction.

This regulatory shift presents both challenges and opportunities for contractors. The main challenge lies in moving away from the traditional plasterboard and mastic approach and adopting new materials and techniques that provide superior airtightness. Contractors will need to explore advanced sealing technologies and integrate them early into the construction process.

Conversely, there is an opportunity for contractors to align with sustainable building practices. Meeting the new airtightness standards ensures buildings with better thermal performance, leading to energy savings and reduced environmental impact. This transition could open new markets for contractors who adapt effectively to these changes.

A critical aspect of the new standards is incorporating airtightness considerations early in the design phase. This approach ensures that airtightness is not an add-on but a fundamental aspect of the building’s design. Architects and designers will need to collaborate closely with contractors to choose appropriate materials and design strategies that comply with the new standards.

The construction industry must also focus on education and training to equip professionals with the necessary knowledge and skills. Training programs emphasizing the latest materials and techniques for achieving airtightness will be crucial for the workforce to adapt to these new standards.

The push towards lower airtightness targets is likely to drive innovation in construction materials and methods. New products designed to meet these stringent requirements are expected to emerge. Moreover, the use of advanced technologies like building information modeling (BIM) can significantly aid in planning and executing projects that adhere to these new airtightness standards.

Three of these technologies will be demonstrated at the Future of Airtightness event, as previously discussed:

- SIGA (membranes and moisture control)

- Passive Purple (airtight ‘paint’, reduces leakage in porous materials)

- Aerobarrier (aerosol liquid membranes finds the gaps in construction and seals them).

In conclusion, the new airtightness targets in Approved Document L represent a pivotal shift in building practices in England and Wales. Moving away from traditional methods like plasterboard and mastic, the construction industry must adopt a holistic approach that integrates airtightness from the design stage. While challenging, this transition is a step towards more sustainable and energy-efficient construction, in line with global environmental goals. The industry must embrace these changes, prioritising innovation, education, and collaboration to achieve these new standards.