Dear Members,

With ambiguity in the industry about the approach to take when testing buildings with plant rooms, the ATTMA provides the following guidance.

Plant Rooms – Dwellings

With buildings becoming smarter and smarter, there is an increased number of plant rooms within dwellings for building services such as mechanical ventilation, data / media servers etc. As these generate heat, they often need to be ventilated. Plant rooms can also be ‘hot water tank cupboards’ or similar.

There are three ‘typical’ set ups for plant rooms:

- The plant room is included in the conditioned space and the air barrier line of the dwelling.

- The plant room is not intentionally ventilated externally, only through ventilation grilles through the door only to ventilate back into the conditioned space of the dwelling.

- The plant room is included in the conditioned space and the air barrier line of the dwelling and is ventilated typically through an extract system of sorts.

The plant room is not included in the conditioned space and services break through the air barrier line. This is typically if the services are located in the loft or in a dedicated void space. This has particular advantages of keeping the services cool.

Temporary Sealing & Plant Rooms – Dwellings

For types 1 and 2, it is never acceptable to temporarily seal the door for the purpose of the test, only close the door. Any temporary sealing of the door will result in the test being rejected by the ATTMA.

It is also never acceptable to temporarily seal any pipes, cables, ventilation ducting or otherwise that break through the air barrier line. These must be permanently sealed with an appropriate sealant (fire retardant if necessary).

It is only acceptable to temporarily seal designed ventilation. ventilation that is deliberately installed and is included in the SAP calculation. Holes in the wall or ‘gaps’ around installations are not considered to be designed ventilation.

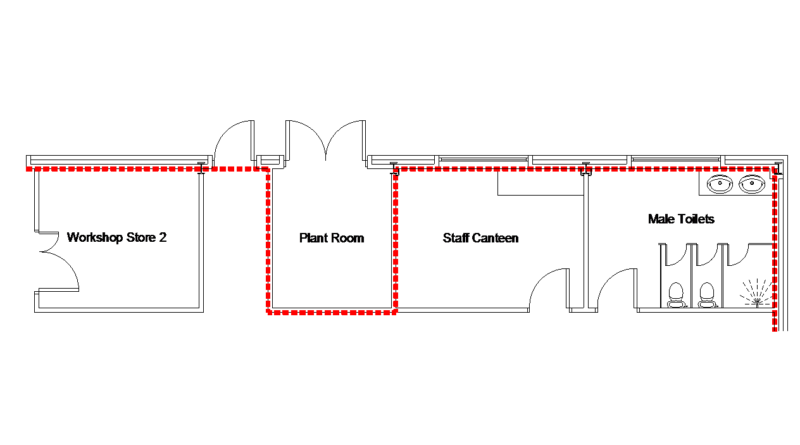

Plant Rooms – Non-Dwellings

Plant rooms for non-dwellings follow the same typical set up as dwellings but on a much larger scale.

- The plant room is included in the conditioned space and the air barrier line of the non-dwelling. The plant room is not intentionally ventilated externally, only through ventilation grilles through the door only to ventilate back into the conditioned space of the non-dwelling.

- The plant room is included in the conditioned space and the air barrier line of the non-dwelling and is ventilated typically through an extract system of sorts.

- The plant room is not included in the conditioned space and services break through the air barrier line. This is typically if the services are located in the loft or in a dedicated void space. For non-dwellings, type 3 plant rooms may have louvre doors on the outside to keep the internal workings of the plant room cool, or to allow air to be drawn in.

Temporary Sealing & Plant Rooms – Non-Dwellings

For types 1 and 2, it is never acceptable to temporarily seal the door for the purpose of the test, only close the door. Any temporary sealing of the door will result in the test being rejected by the ATTMA.

For type 3, the wall between the plant room and the conditioned space becomes the air barrier. It is never acceptable to temporarily seal any pipes, cables, ventilation ducting or otherwise that break through the air barrier line. These must be permanently sealed with an appropriate sealant (fire retardant if necessary). It is also not acceptable to temporarily seal any ventilation into the plant room for the purposes of the test, such as louvres, doors, windows or otherwise as this is not typical of normal building use and will give a false result.

The same theory applies for external rooms within the building envelope, say for example in school halls you may have an external storage area that cannot be accessed internally. It is not acceptable to temporarily seal the external doors to prevent leakage going through the wall between the internal conditioned space and the storage room. This could also apply to lifts, under-crofts integral garages etc.

If you are unsure, or if your plant room situation does not match one of the types identified above, please contact me for further guidance. I am more than happy to discuss individual requirements to ensure that testing is carried out in strict accordance with the test standards.