- About ATTMA

What Is Air Tightness Testing

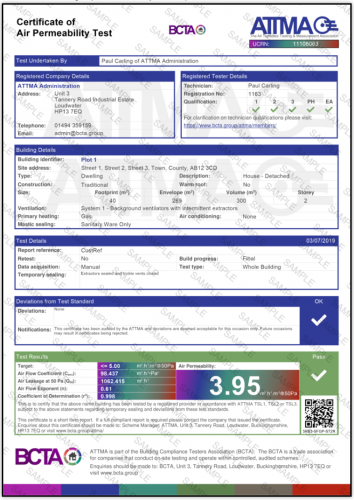

- Certification

AIR TIGHTNESS TESTING

AIR TIGHTNESS TESTING SCOPE

UK AND EUROPE

Scheme Requirements

AUSTRALIA AND NEW ZEALAND

Scheme Requirements

VENTILATION

DOMESTIC VENTILATION COMMISSIONING SCOPE

APPLY

Scheme Requirements

- Members

United Kingdom

European Union

Australia

United Arab Emirates

New Zealand

Asia

ATTMA DOMESTIC VENTILATION COMMISSIONING

united kingdom

- Training

APPROVED TRAINING PARTNERS

- ATTMA News

ATTMA News

ATTMA ANZ News

ATTMA FAQ's

- ATTMA Tools

Fan Calibration Variable Calculator

Fan Capacity Calculator

Technical Standards Comparison

Testing Software Comparison

Air Tightness Testing Requirements by Country

- Downloads

- Lodgement

Certificate Validation

The ATTMA App

What is ATTMA Lodgement?

Lodgement Updates

Login to ATTMA Lodgement