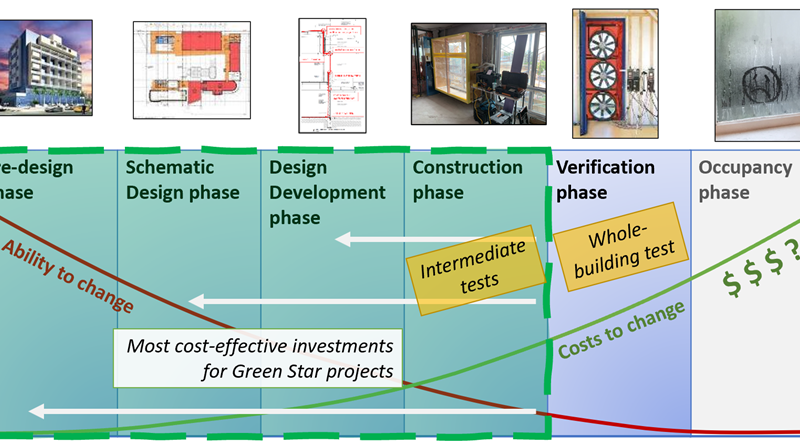

Green Star Buildings requires essentials of the Building Enclosure Commissioning (BECx) process. Air tightness testing is just one part. A good result for a whole-building test at the end gives you more confidence that prior steps in the process were addressed. But how do you maximise your chances of success?

An ATTMA tester who has done many whole-building tests will know where problems commonly arise and will have suggestions on how to address them as early as possible. The sooner you identify problems in the design phase, the more cost-effective the remedies will be. An effective BECs process begins long before the design is complete.

Steps in the Building Enclosure Commissioning process for air tightness are outlined further below.

Ask your ATTMA tester what experience they have with the following key steps in the Building Enclosure Commissioning (BECx) process:

Pre-Design Phase

Clarify the Owner’s Project Requirements (OPR) and set whole-building air tightness goals that could meet them. Make the goals too easy, and you’ll miss the energy and building durability benefits of air tightness. Make them too hard, and your client may be disappointed.

Schematic Design Phase

Clarify the big decisions that affect whole-building performance. Which spaces are conditioned or unconditioned? Are there spaces with special needs (e.g. aquatic, theatre/performance, cold storage, server rooms)? What is the Basis of Design for the enclosures of each space and is it likely to meet the OPR? See how different levels of air tightness affect performance in the energy model.

Design Development Phase

Review the plans for air barrier continuity – it’s not just about specific air barrier products, but how do they join? Are the sealants and materials compatible? How does the wall air barrier assembly join the roof? How does it join the floor? Is each assembly good enough to meet the OPR?

Construction Phase

In a pre-construction meeting, get EVERYONE in the room who is affected by the air barrier design – the client, main contractor, façade consultant, and any subcontractors for windows, roof and walls – to discuss the sequence of installation and try to iron out problems before they cost more money. Observe tests of mock-ups ASAP and apply the findings going forward. Qualitative tests of building sections to identify and remediate leakage points are a specialty of ATTMA testers.

Verification Phase

A whole-building test is the best way to gauge overall effectiveness of the BECx process for air tightness. An ATTMA Level 2 or Level 3 tester is required for large buildings, but a Level 1 tester can readily test smaller buildings, homes, and multi-res units. Make sure your test is legitimate!

Occupancy Phase

You don’t want your ultimate client – the owner or occupants – to find building enclosure problems. That means they’ve been given a bad product. Rely on your ATTMA tester as a key part of the Building Enclosure Commissioning process and integrate them as early as possible along with your façade consultants, waterproofing specialists, and contractors.

Follow ATTMA Australia and New Zealand on LinkedIn for events and resources to help you deliver better projects!